Let you get higher efficiency.

Choose the international and domestic first-line brand laser.

Non-contact sensor, automatic detection of the actual plate position;

Automatic collimation focusing, no need to wait for material replacement, making processing more efficient;

Automatic positioning, automatic following, collision avoidance, collision avoidance and other functions;

Stepless zoom perforation improves the efficiency of thick plate perforation by 3-5 times.

Real-time monitoring of temperature and pressure to ensure cutting section quality;

Follow - up focus compensation, focus displacement control, to ensure the stability of continuous cutting.

Based on Windows platform, the interface is clear and easy to learn;

Complete cutting process database, real-time adjustment, the best cutting quality;

Support a variety of graphics format input and international G code;

Automatic typesetting function, can automatically co-edge, generate residual material, through a variety of arrays will be full of plates;

Powerful editing ability, zoom, translation, combination, slit compensation, micro connection, bridge,

flight cutting, breakpoint memory and more than 30 cutting functions;

A variety of automatic edge finding methods, accurate positioning, support fixed height cutting and plate outside following;

Support wireless handheld box, and Ethernet remote control.

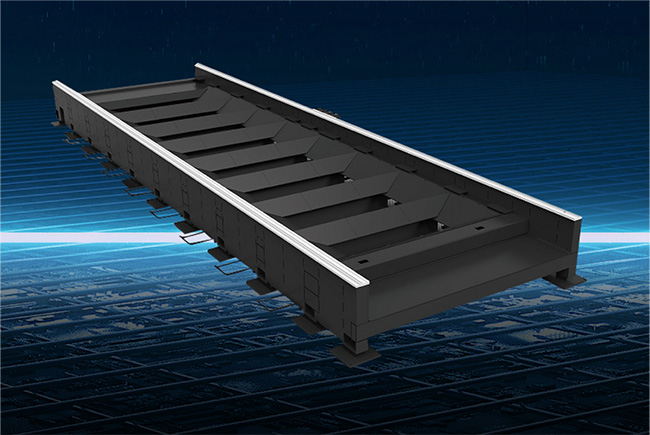

After 650 degrees high temperature aging treatment of CNC electric furnace, 24 hours of natural cooling, completely eliminate the welding stress of machine tool;

Large gantry milling machine a molding, the gantry grinder grinding processing, to ensure the uniformity and high precision of both sides of the machine;

The machine is covered with anti-burning plate to prevent the influence of laser waste heat on the machine and prevent the thermal deformation of the machine;

Partition dust pumping box, laser waste heat flow in the dust pumping box, improve the service life of the machine;

Automatic oil supply and lubrication system, reduce the thermal absorption of machine tools, to ensure long-term operation accuracy of machine tools.