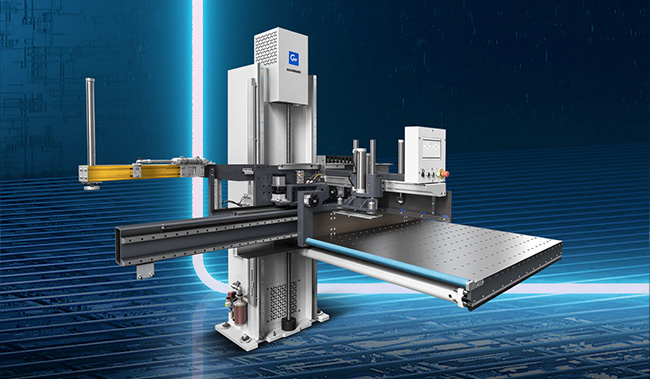

QT-2 / QT-4

This machine has the function of automatic paper stacking and loading, can quickly and automatically transfer the paper in the paper stacking to the working platform. Infrared position detection device, accurate detection of the position of the paper to ensure that the paper stacked neatly, collision protection flexible bumper, in the machine movement effectively prevent accident impact pneumatic manipulator safety clamping device, flexible clamping paper, protect the edge of the paper from external force crimping deformation

Can set the height of the paper, according to the paper situation, to ensure that the paper is not damaged. New adjustment of the paper roll movement mode, can maximize the protection from damage. Fast replaceable paper loading roller greatly improves equipment maintenance efficiency. The work platform is equipped with blowing structure, convenient to move the paper, pneumatic manipulator safety clamping device, flexible clamping paper, protect the edge of the paper from external force curved to deformation.

QS-2 / QS-4

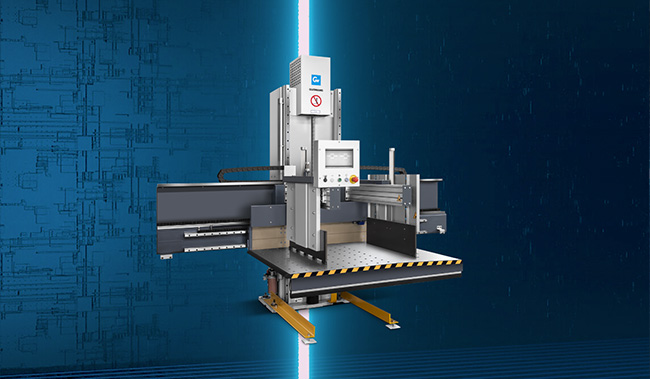

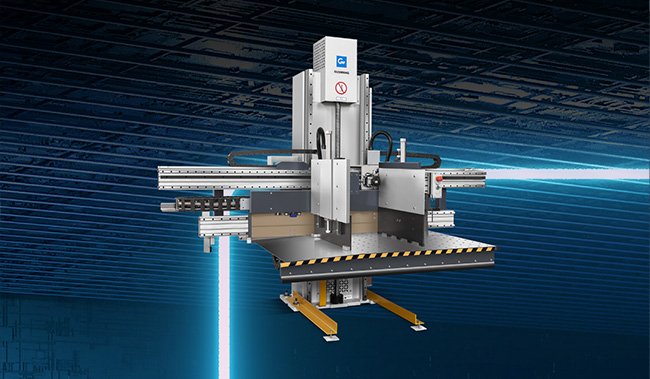

GT-2 / GT-4

This machine has the function of automatic paper stacking and loading, can quickly and automatically transfer the paper in the paper stacking to the working platform. Infrared position detection device, accurate detection of paper position, to ensure that paper stacked neatly. Anti-collision flexible bumper, effectively prevent accidental collision in machine movement. Pneumatic manipulator safety clamping device, to achieve flexible clamping paper, protect the edge of the paper from external force curved to deformation.

This machine has the function of automatic paper stacking and loading, can quickly and automatically transfer the paper in the paper stacking to the working platform. Infrared position detection device, accurate detection of paper position, to ensure that paper stacked neatly. Anti-collision flexible bumper, effectively prevent accidental collision in machine movement. Pneumatic manipulator safety clamping device, to achieve flexible clamping paper, protect the edge of the paper from external force curved to deformation.

GS-2 / GS-4

LT-1 / LT-2 / LT-3 / LT-4

It can be used as a paper lift machine or a paper drop machine. Adopt Italian hydraulic station to provide strong power. Oil circuit design meets CE requirements, anti-explosion design. Can move the paper pile up and down, reduce labor cost, improve efficiency

The machine can improve efficiency, ensure the continuity of cutting, greatly improve the output of material, with automatic double exhaust function, the paper leveling greatly improve the precision of cutting, for the final quality of the final product lay a good foundation. Lifting, exhaust using Germany imported motor, stable performance, low noise, fully guarantee the service life of the machine can choose the American imported weighing device, more convenient and fast paper counting

JPA-2

| Model | QT-2 | QT-4 |

| Min. size(Y) | 400 mm | 600 mm |

| Min. size(X) | 600 mm | 850 mm |

| Max. size(Y) | 960,920 mm | 1300,1250 mm |

| Max. size(X) | 1350 mm | 1680 mm |

| Min. height of each batch | 55 mm | 55 mm |

| Max. height of each batch | 165 mm | 165 mm |

| Max. stacking height | 1600 mm | 1600 mm |

| Loading capacity | 300 kg | 480 kg |

| Unloading time | 40-55 S | 40-55 S |

| Noise level | 75 dB | 75 dB |

| Model | QT-2 | QT-4 |

| Machine width | 3300 mm | 4450 mm |

| Machine depth | 1910 mm | 2560 mm |

| Machine height | 2412 mm | 2640 mm |

| Net weight | 1600 kg | 2500 kg |

| Compressed air pressure | 5-8 bar | 5-8 bar |

| Air flow | 4 L/Min | 4 L/Min |

| Consumed power (Max.) | 4 KW | 8 KW |

| Max. safe current | 10 A | 20 A |

| Voltage | 380±5% V / 50 HZ | 380±5% V / 50 HZ |

| Packing size | 2700x2050x2487 mm | 2540x3500x2867 mm |

| Model | QS-2 | QS-4 |

| Min. size(Y) | 400 mm | 600 mm |

| Min. size(X) | 600 mm | 850 mm |

| Max. size(Y) | 1100,1060 mm | 1300,1250 mm |

| Max. size(X) | 1350 mm | 1680 mm |

| Min. height of each batch | 55 mm | 55 mm |

| Max. height of each batch | 165 mm | 165 mm |

| Max. stacking height | 1600 mm | 1600 mm |

| Loading capacity | 380 kg | 480 kg |

| Unloading time | 40-55 S | 40-55 S |

| Noise level | 75 dB | 75 dB |

| Model | QS-2 | QS-4 |

| Machine width | 3770 mm | 4450 mm |

| Machine depth | 2080 mm | 2560 mm |

| Machine height | 2412 mm | 2640 mm |

| Net weight | 1604 kg | 2500 kg |

| Compressed air pressure | 5-8 bar | 5-8 bar |

| Air flow | 4 L/Min | 4 L/Min |

| Consumed power (Max.) | 4 KW | 8 KW |

| Max. safe current | 10 A | 20 A |

| Voltage | 380±5% V / 50 HZ | 380±5% V / 50 HZ |

| Packing size | 2320x3200x2487 mm | 2540x3500x2867 mm |

| Model | GT-2 | GT-4 |

| Min. size (Y) | 400 mm | 500 mm |

| Min. size (X) | 400 mm | 500 mm |

| Max. size (Y) | 1050 mm | 1240 mm |

| Max. size (X) | 1280 mm | 1650 mm |

| Min. height of each batch | 40 mm | 40 mm |

| Max. height of each batch | 165 mm | 165 mm |

| Max. stacking height | 1600 mm | 1600 mm |

| Loading capacity | 300 kg | 420 kg |

| Unloading time | 30-40 S | 30-40 S |

| Noise level | 75 dB | 75 dB |

| Model | GT-2 | GT-4 |

| Machine width | 3240 mm | 4000 mm |

| Machine depth | 1807 mm | 2290 mm |

| Machine height | 2427 mm | 2640 mm |

| Net weight | 1440 kg | 2800 kg |

| Compressed air pressure | 5-8 bar | 5-8 bar |

| Air flow | 5 L/Min | 6 L/Min |

| Consumed power (Max.) | 4 KW | 8 KW |

| Max. safe current | 10 A | 20 A |

| Voltage | 380±5% V / 50 HZ | 380±5% V / 50 HZ |

| Packing size | 3150x2100x2250 mm | 4200x2450x3960 mm |

| Model | GS-2 | GS-4 |

| Min. size (Y) | 400 mm | 500 mm |

| Min. size (X) | 400 mm | 500 mm |

| Max. size(Y) | 1050 mm | 1240 mm |

| Max. size(X) | 1280 mm | 1650 mm |

| Min. height of each batch | 40 mm | 40 mm |

| Max. height of each batch | 165 mm | 165 mm |

| Max. stacking height | 1600 mm | 1600 mm |

| Loading capacity | 300 kg | 420 kg |

| Unloading time | 30-40 S | 30-40 S |

| Noise level | 75 dB | 75 dB |

| Model | GS-2 | GS-4 |

| Machine width | 3240 mm | 4000 mm |

| Machine depth | 1807 mm | 2290 mm |

| Machine height | 2427 mm | 2640 mm |

| Net weight | 1440 kg | 2800 kg |

| Compressed air pressure | 5-8 bar | 5-8 bar |

| Air flow | 5 L/Min | 6 L/Min |

| Consumed power (Max.) | 4 KW | 8 KW |

| Max. safe current | 10 A | 20 A |

| Voltage | 380±5% V / 50 HZ | 380±5% V / 50 HZ |

| Packing size | 3150x2100x2250 mm | 4200x2450x3960 mm |

| Model | LT-1 | LT-2 | LT-3 | LT-4 |

| Inner platform Max. size(Y) | 620 mm | 840 mm | 1090 mm | 1240 mm |

| Inner platform Max. size(X) | 900 mm | 1270 mm | 1520 mm | 1700 mm |

| Max. working range (stack) | 850 mm | 850 mm | 900 mm | 9000 mm |

| Max. loading amount | 450 mm | 1200 mm | 1200/2000 mm | 2000 mm |

| Noise level(EN13023) | 77,9 dB | 77,9 dB | 77,9 dB | 77,9 dB |

| Packing size | 1370x1250x1800 mm | 1480x1810x1800 mm | 1750x2110x1800 mm | 1940x2150x1940 mm |

| Model | LT-1 | LT-2 | LT-3 | LT-4 |

| Width(B) | 1050 mm | 1610 mm | 1910 mm | 1950 mm |

| Depth(A) | 1170 mm | 1280 mm | 1550 mm | 1740 mm |

| Height | 1500 mm | 1500 mm | 1500 mm | 1640 mm |

| The Max. working range height | 2100 mm | 2100 mm | 2100 mm | 2120 mm |

| Net weight | 500 kg | 630 kg | 770 kg | 1100 kg |

| Power voltage | 380±5% V / 50 HZ | 380±5% V / 50 HZ | 380±5% V / 50 HZ | 380±5% V / 50 HZ |

| Consumed power (Max.) | 1 KW | 1.2 KW | 1.2 KW | 1.6 KW |

| Max. safe current | 6 A | 6 A | 6 A | 6 A |

| Model | JPA-2 |

| Working table size(A) | 900 mm |

| Working table size(B) | 1150 mm |

| Jogging paper height | 165 mm |

| Working table height | 880-980 mm |

| Packing size | 1750x1490x1300(2180) mm |

| Model | JPA-2 |

| Width(C) | 950 / 1550 mm |

| Depth(D) | 1290 mm |

| Height | 1100 / 1875 mm |

| Net weight | 550 kg |

| Compressed air pressure | 5-8 bar |

| Air flow | 5 L/Min |

| Power voltage | 380±5% V / 50 HZ |

| Consumed power (Max.) | 2 KW |

| Max. safe current | 6 A |