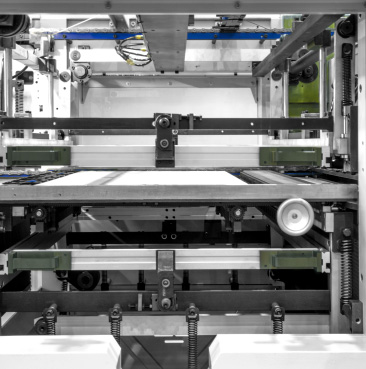

Precise product positioning: single feed plus multi-station adjustable positioning structure for more precise registration and better looking products.

Outstanding versatility: foil stamping, embossing and holographic applications Stamping on a wide range of materials, including diffraction stamping with complex structural images.

Diversification of the product range: a single machine can fulfill your stamping and die-cutting needs and can help you to build up your stamping work orders while being used as a die-cutting machine on a daily basis.

Efficient and cost-saving: fast changeover from stamping to die-cutting with virtually no downtime due to foil breakage Equipped with a dedicated system for efficient production data management.

User-friendly operation interface: The stamping part is equipped with a 19-inch high-definition touch screen, all settings as well as functions can be easily realized by touching Based on the special knowledge of the equipment, we have developed a characteristic operation and control system, which is simple, intuitive and easy to operate.