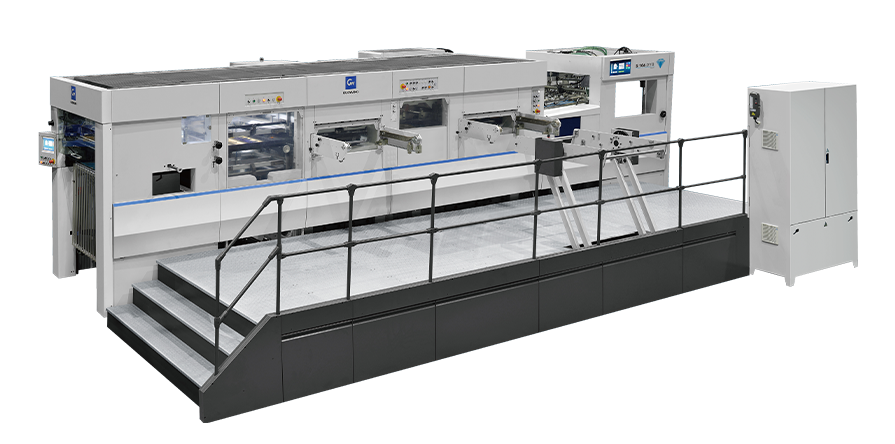

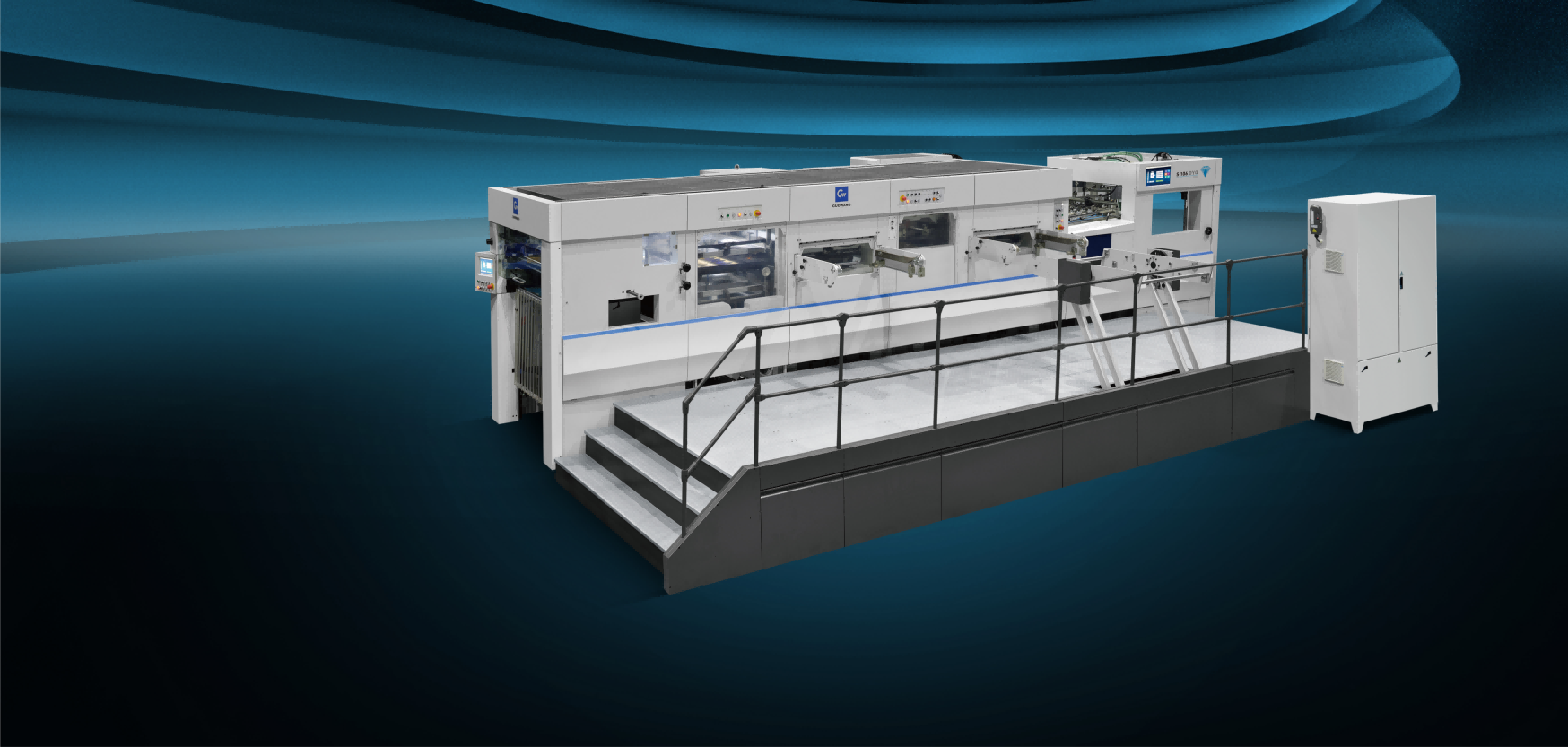

Double Efficiency Enhancement: Dual platform structure design, double efficiency enhancement, greatly reducing the cost and making your products more competitive.

Outstanding versatility: the application of hot stamping, embossing and holographic patterns can be stamped on a variety of materials, including diffraction stamping with complex structural images.

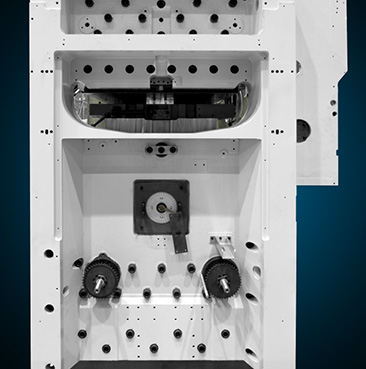

Multi-process combination: Combine the functions of the equipment according to the different process requirements of the product, so that the equipment can meet a variety of process requirements at one time and produce satisfactory products.

High efficiency and cost saving: fast changeover from hot stamping to die-cutting with almost no downtime due to foil breakage Equipped with a dedicated system for efficient production data management.

Humanized operation interface: the hot stamping part adopts 19-inch high-definition touch screen, all the settings as well as functions can be easily realized by touching based on the special cognition of the equipment, the operation and control system with special features is developed, simple, intuitive and easy to operate.