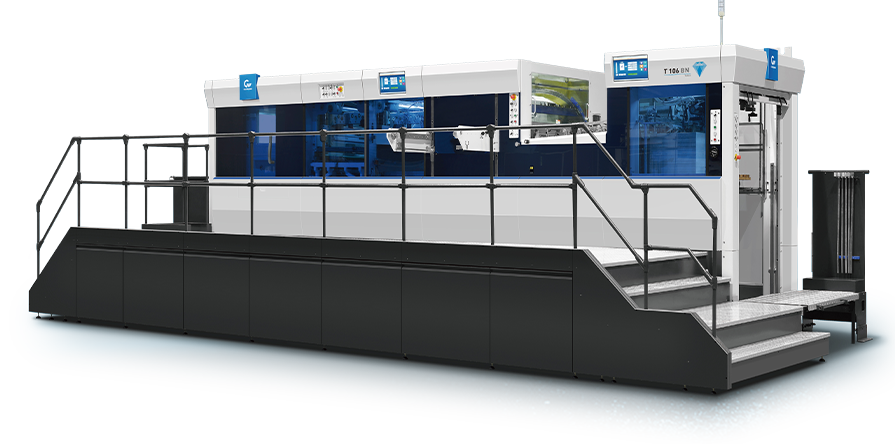

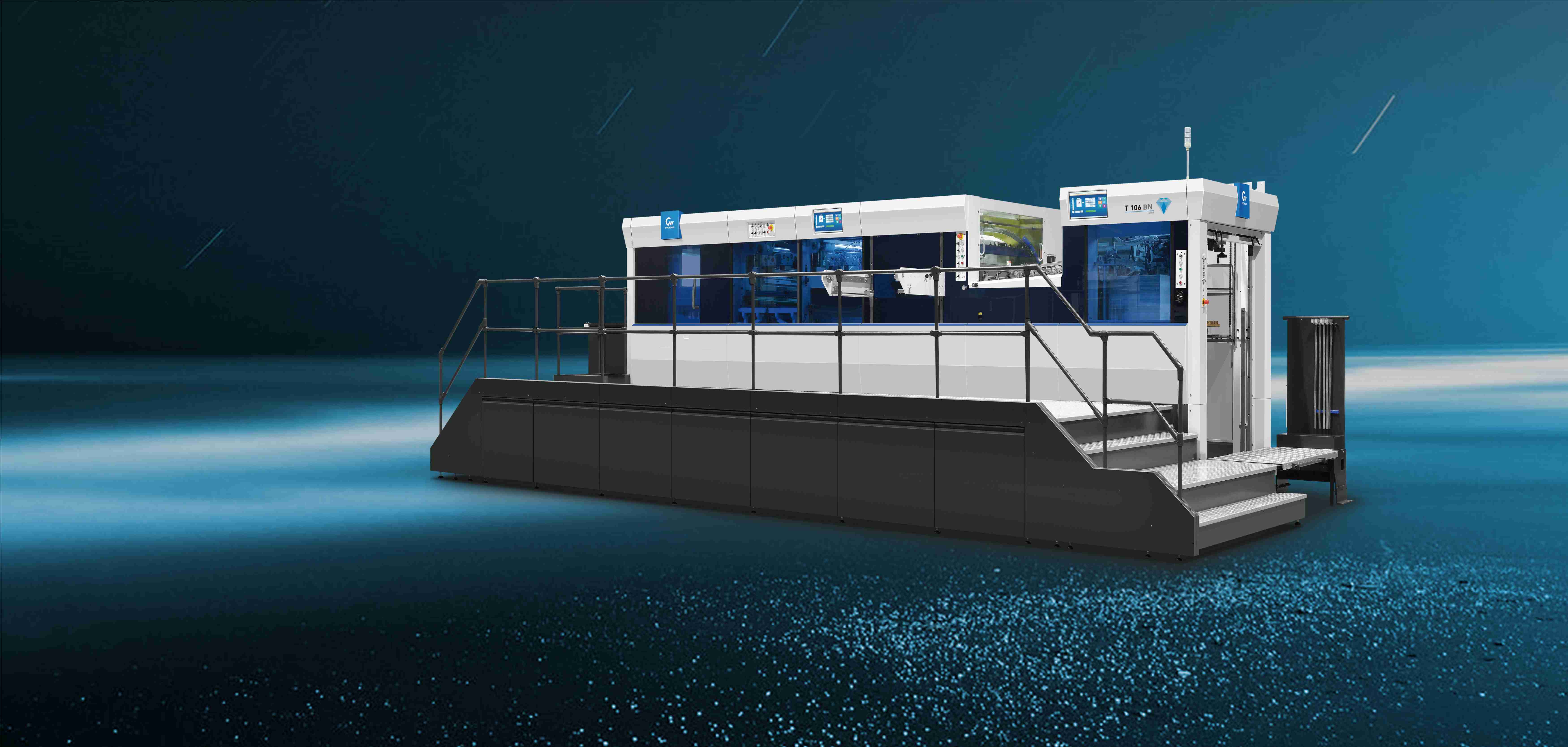

Die cut and clear waste in one pass: Immediate generation of high quality stacked and counted batches, significantly reducing workload and associated costs, complete paper collection for short-run, non-repetitive orders.

No downtime production: less setup and order changeover time, resulting in increased throughput Intelligent infeed table and unique die-cut-to-print registration significantly reduces feeder-related downtime.

Die cut, clear waste conversion: Multi-purpose machine capable of flexible conversion between die cut and clear waste.

Time-saving ergonomics: fast changeover from die-cutting to waste removal for efficient production data management.

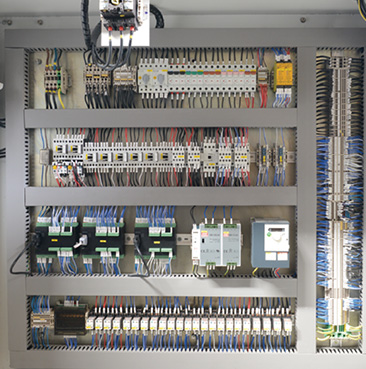

Humanized operation interface: the stamping part adopts 19-inch high-definition touch screen, all the settings and functions can be easily realized by touching based on the special knowledge of the equipment, the development of a characteristic operation and control system, simple, intuitive and easy to operate.