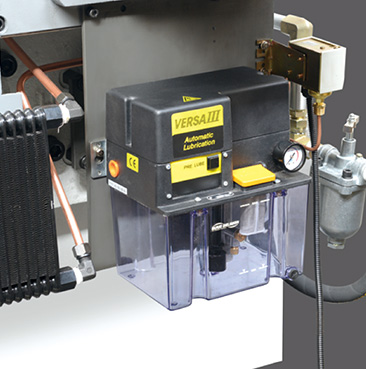

Safety: perfect safety monitoring system, real-time protection of operators and equipment safety, eliminating your concerns about safety.

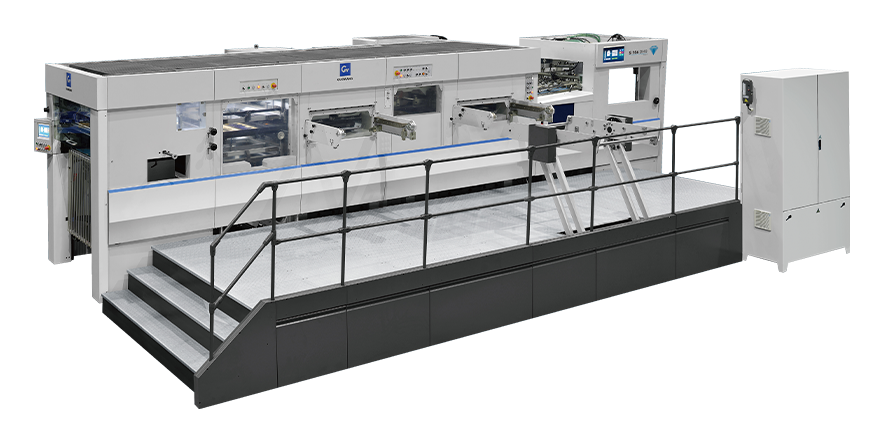

High versatility of parts: the parts of the double platform are highly versatile and interchangeable, which is convenient for maintenance and improves the production efficiency, and greatly saves the number of parts and material costs in the warehouse.

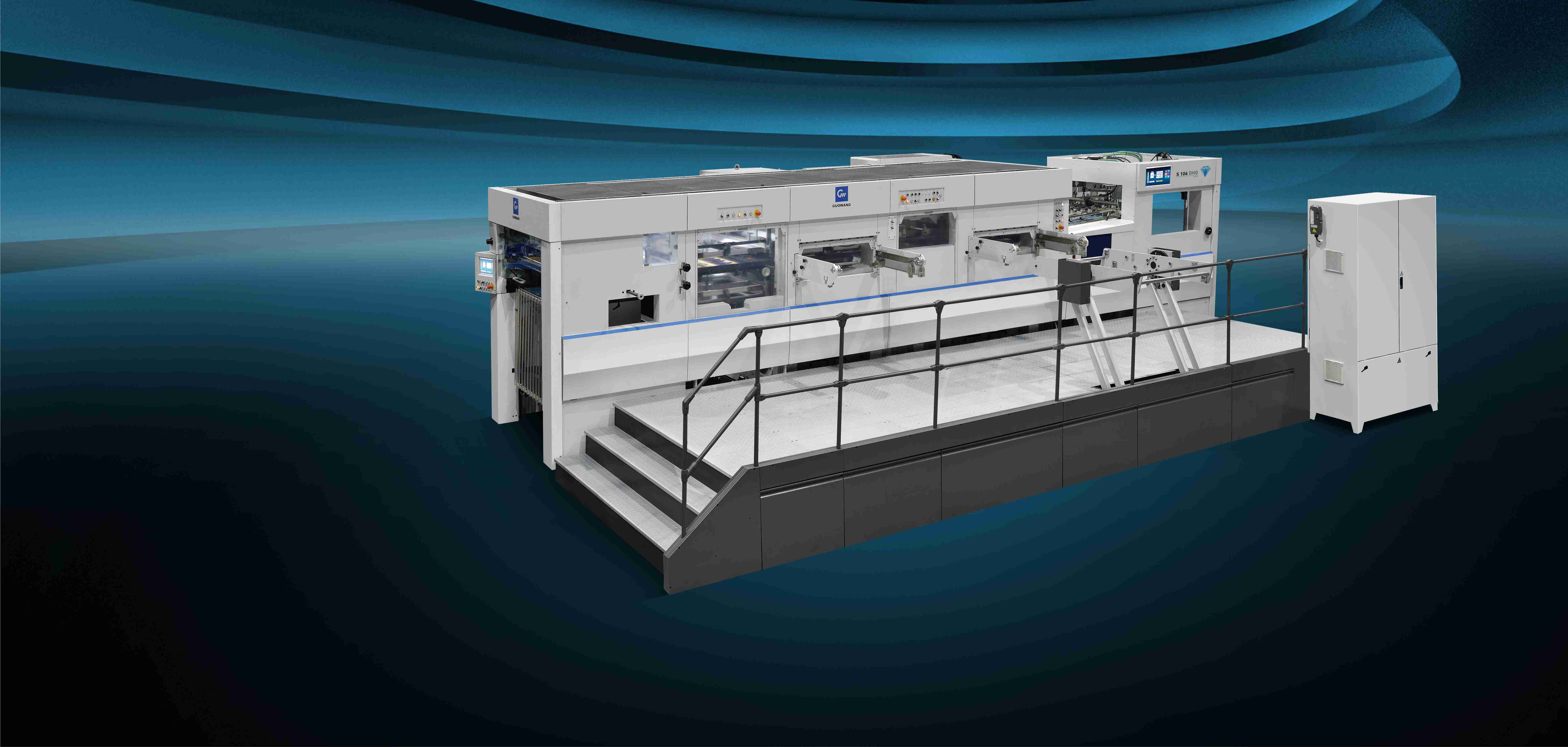

Perfect action coordination: the one-piece transmission linkage structure highly guarantees the consistency and coordination of the double-platform action, and the double-code detection ensures the safety and reliability of the equipment.

Double efficiency enhancement: double platform structure design, double efficiency enhancement, greatly reducing the cost, so that your products are more competitive.

Humanized operation interface: the stamping part adopts 19-inch high-definition touch screen, all the settings and functions can be easily realized by touching based on the special knowledge of the equipment, the development of a characteristic operation and control system, simple, intuitive, easy to operate.