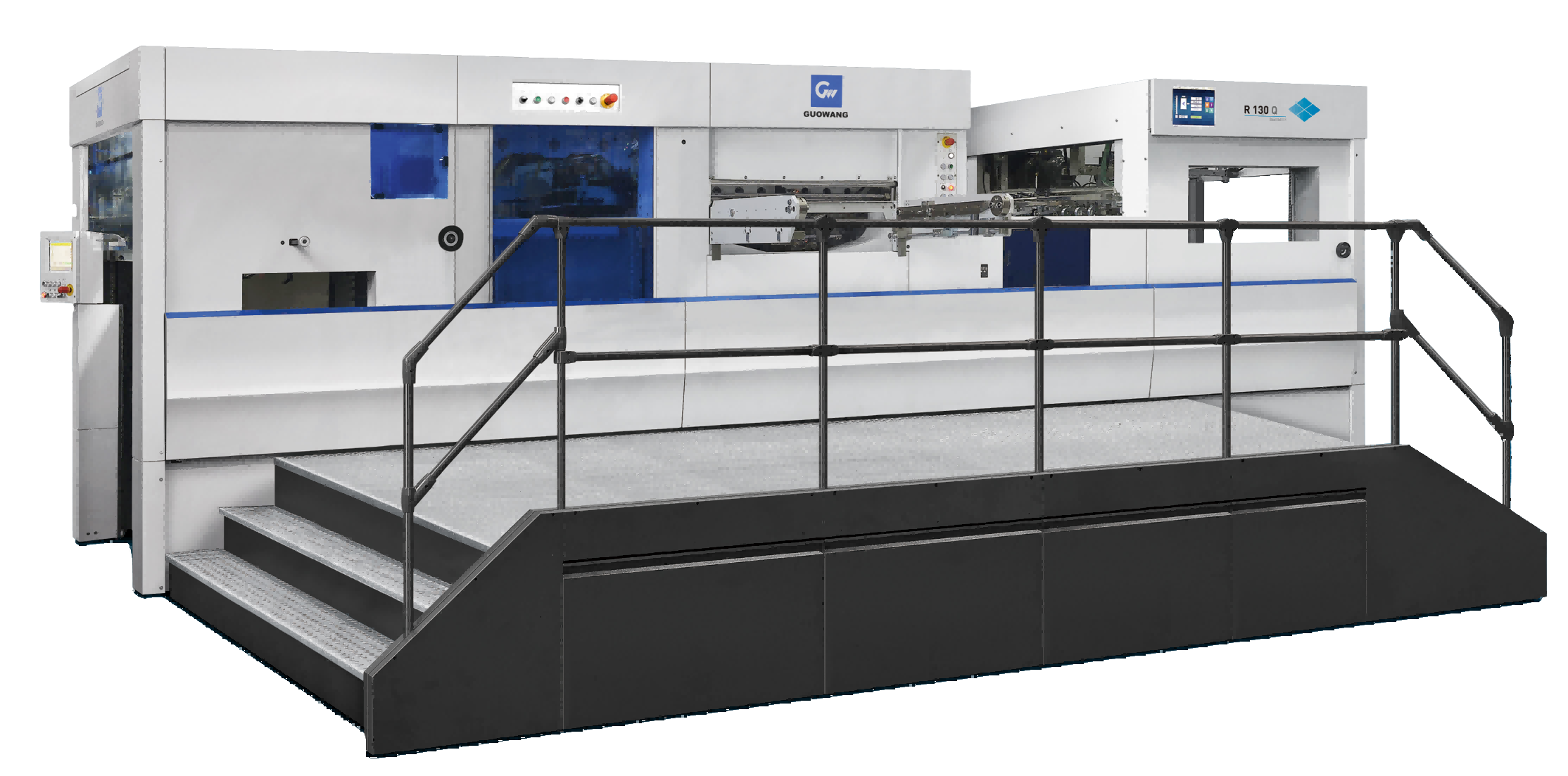

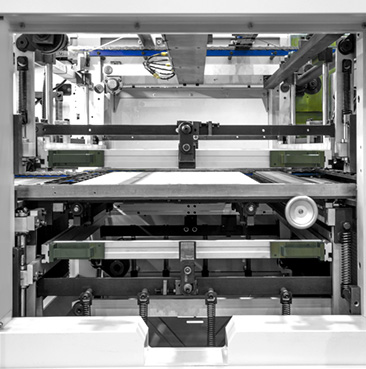

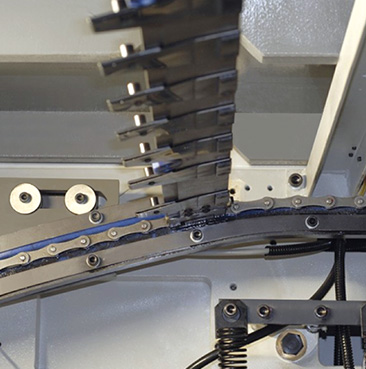

Die cut and clear waste in one pass: instantly generates quality stacked and counted batches, significantly reducing workload and associated costs, complete paper collection for short-run, non-repetitive orders.

No downtime production: less setup and order changeover time, resulting in increased throughput, intelligent infeed table and unique die cut to print registration, significantly reduces feeder related downtime.

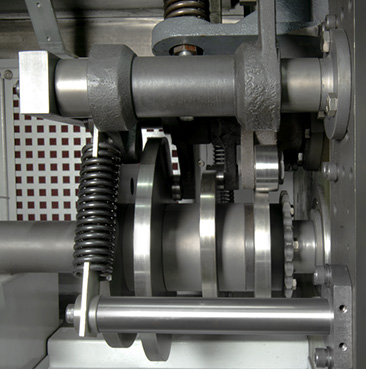

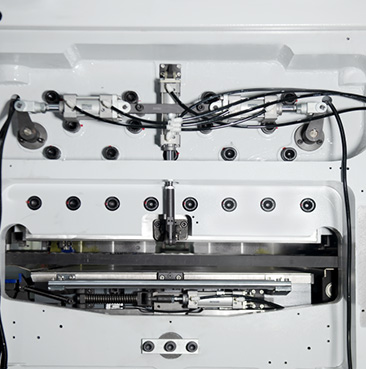

Die-cutting and scrap-cleaning conversion: Multi-purpose machine capable of flexible conversion between die-cutting and scrap-cleaning.

Time-saving ergonomics: fast changeover from die-cutting to waste removal for efficient production data management.

Humanized operation interface: the stamping part adopts 19-inch high-definition touch screen, all the settings as well as functions can be easily realized by touching Based on the special knowledge of the equipment, the operation and control system with special features is developed, which is simple, intuitive and easy to operate.