Less time in adjusting setting and setting order so as to increase from intelligent conveyor platform and unique die-cutting to printing registration, which can greatly reduce downtime on feeding.

Die-cutting and embossing can be available in one machine.

Fast conversion from die-cutting to stripping achieves efficient production data management.

For offset laminating and folding carton products, the die cutting machine is highly efficient and can truly improve your competitive advantage.

| Model | T 106 QN |

| Max. sheet size | 1060 × 760 mm |

| Min. sheet size | 400 × 350 mm |

| Max. cutting size | 1045 × 745 mm |

| Die size | 1075 × 765 mm |

| Cutting plate | 4+1 mm |

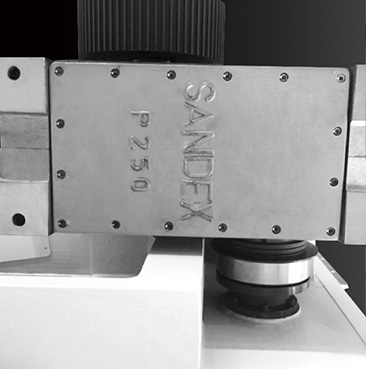

| Height of die-cutting rule | 23.8 mm |

| First cutting rule | 13 mm |

| Gripper margin | 7-17 mm |

| Carton board | 90-2000 g/㎡ |

| Carton board | 0.1-3 mm |

| Corrugated board | ≤4 mm |

| Max. cutting force | 350 t |

| Max. die-cutting speed | 7500 S/H |

| Feeder pile height (incl. pallet) | 1800 mm |

| Non-stop feeder pile height (incl. pallet) | 1300 mm |

| Delivery pile height (incl. pallet) | 1600 mm |

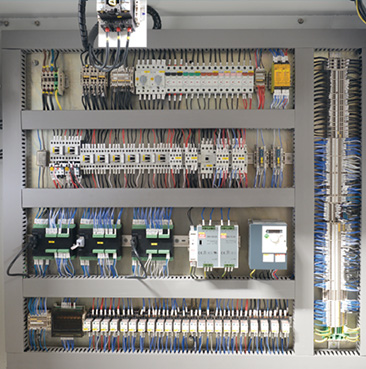

| Main motor power | 11 KW |

| Machine power | 17 KW |

| Voltage | 380±5% V / 50 HZ |

| Cable | 10 m㎡ |

| Compressed air | 6-8 bar |

| Air flow | 200 L/Min |

| Model | T 106 QN |

| A Overall machine length | 7800 mm |

| B Overall machine length | 4720 mm |

| C Overall height of machine | 2700 mm |

| D Cat walk way length | 7200 mm |

| E Cat walk way width | 2500 mm |

| F Machine length | 6280 mm |

| G Machine width | 2260 mm |

| J Aisle for paper feeding | 2500 mm |

| K Aisle of machine side | 1500 mm |

| L Aisle for paper delivery | 2000 mm |

| Net weight | 18.5 t |

| Packing size length | 6600 mm |

| Packing size width | 2320 mm |

| Packing size height | 2950 mm |

Gift box

Packing

Cosmetics box

Graphic carton