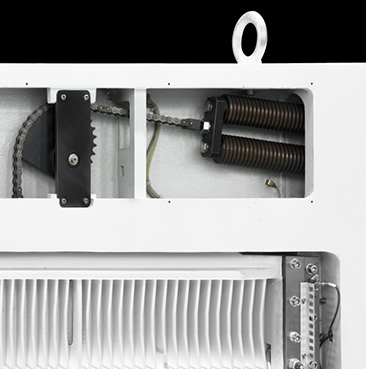

Built-in knife back safety structure and highly reliable hands protection safety photoelectric ensures the operator

The cutting parts are equipped with automatic lubrication system, which improves the working efficiency and prolongs the service life of equipment.

The main low-voltage control part of the whole machine adopts imported electrical appliances, including OMRON, Panasonic, Schneider, EATON and so on.

The operation screen of the computer adopts humanized design, so that the operator is easy to operate.

| Model | GW 80 P | GW 92 P | GW 115 P | GW 130 P | GW 137 P | GW 176 P |

| H Max. cutting length | 800 mm | 920 mm | 1150 mm | 1300 mm | 1450 mm | 2000 mm |

| I Max. cutting width | 800 mm | 920 mm | 1150 mm | 1300 mm | 1370 mm | 1760 mm |

| J Max. cutting height | 130 mm | 130 mm | 165 mm | 130 mm | 165 mm | 165 mm |

| Min. cutting (without presser) | 20 mm | 25(22) mm | 25 mm | 25 mm | 25 mm | 35 mm |

| Min. cutting (with presser) | 55 mm | 90(70) mm | 75 mm | 85 mm | 75 mm | 120 mm |

| K Cutting point front area length | 690 mm | 690 mm | 735 mm | 735 mm | 735 mm | 750 mm |

| L Cutting point back area length | 1240 mm | 1360 mm | 1605 mm | 1765 mm | 1925 mm | 2620 mm |

| M Height of working table | 900 mm | 900 mm | 900 mm | 900 mm | 900 mm | 900 mm |

| N Auxiliary platform length | 485(650) mm | 485(650) mm | 650(750) mm | 650(750) mm | 650(750) mm | 650(750) mm |

| S Auxiliary width | 600(750) mm | 600(750) mm | 750(1000) mm | 750(1000) mm | 750(1000) mm | 750(1000) mm |

| Presser pressure (Min.) | 1.5 KN | 1.5 KN | 1.5 KN | 2 KN | 1.5 KN | 3 KN |

| Presser pressure (Max.) | 30 KN | 30 KN | 45 KN | 40 KN | 45 KN | 70 KN |

| Blade size | 12.7 mm | 12.7 mm | 13.75 mm | 12.7 mm | 13.75 mm | 13.75 mm |

| Grinding length (Max.) | 30 mm | 30 mm | 60 mm | 30 mm | 60 mm | 60 mm |

| Cutting speed | 45 Pime/min | 45 Pime/min | 45 Pime/min | 45 Pime/min | 45 Pime/min | 45 Pime/min |

| Main power | 3 KW | 3 KW | 4 KW | 4 KW | 4 KW | 7.5 KW |

| Voltage | 380±5% V / 50 HZ | 380±5% V / 50 HZ | 380±5% V / 50 HZ | 380±5% V / 50 HZ | 380±5% V / 50 HZ | 380±5% V / 50 HZ |

| Cable | 2.5 mm² | 2.5 mm² | 2.5 mm² | 2.5 mm² | 2.5 mm² | 4 mm² |

| Model | GW 80 P | GW 92 P | GW 115 P | GW 130 P | GW 137 P | GW 176 P |

| A Machine overall length | 1995(2115) mm | 2070(2235) mm | 2500(2600) mm | 2640(3090) mm | 2823(2923) mm | 3480 mm |

| B Machine overall width | 2105(2305) mm | 2328(2478) mm | 2680(3150) mm | 2850(2950) mm | 2900(3400) mm | 3760 mm |

| C Machine overall height | 1622 mm | 1622 mm | 1680 mm | 1622 mm | 1680 mm | 1730 mm |

| D Machine foundation length | 700 mm | 700 mm | 750 mm | 750 mm | 750 mm | 800 mm |

| E Machine foundation height | 700 mm | 700 mm | 750 mm | 750 mm | 750 mm | 800 mm |

| F Machine foundation thickness | 150 mm | 150 mm | 200 mm | 200 mm | 200 mm | 250 mm |

| G Machine body half width | 762 mm | 822 mm | 978 mm | 1012 mm | 1088 mm | 1288 mm |

| Net weight | 2200 kg | 2800 kg | 3800 kg | 3500 kg | 4500 kg | 7500 kg |

| Packing size | 2250 × 1400 × 1850 mm | 2250 × 1400 × 1910 mm | 2650 × 1500 × 2000 mm | 2750 × 1400 × 1910 mm | 2950 × 1550 × 2000 mm | 3700 × 1600 × 2300 mm |

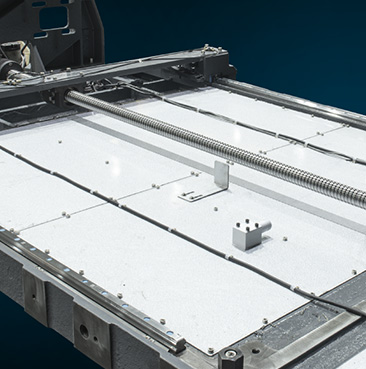

Honeycomb Plate

Carton board

Heavy solid board

Plastic board